Option: Microcontroller

Reference number: L2S-MC-Option

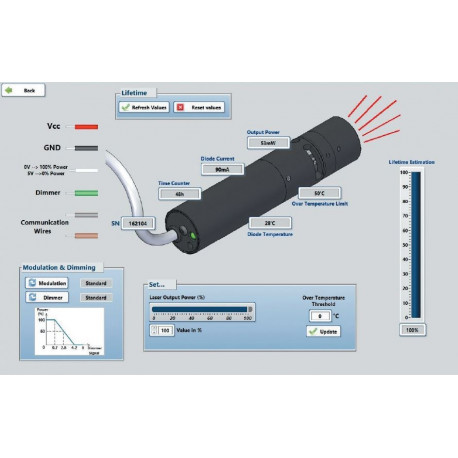

Monitor and control your single laser or even up to 32 at the same time with the microcontroller option.