Description

Almost limitless application possibilities In recent years, the use of lasers and thus also of beam positioning systems has been advanced in many areas. When used with the appropriate scanners, galvanometer motors are one of the fastest options for laser beam positioning, offering impressive precision and speed.

Compared to conventional marking and labeling, non-contact application by means of laser scanners has enjoyed economic recognition in recent years and continues to expand. The variety of applications in connection with metals, plastics, wood, and now also fruits and vegetables, makes the use of scanners an indispensable tool.

But scanners are also indispensable in other areas, such as the welding of metals and plastics, as well as ablation, i.e. vaporization using short-pulse lasers.

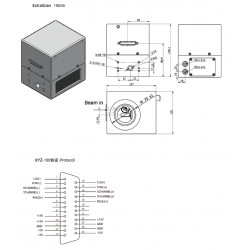

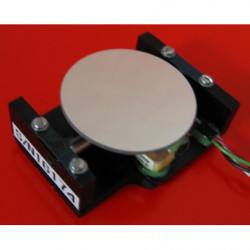

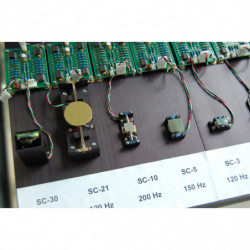

The cost-efficient ExtraScan of Hans Scanner (a company of Hans Laser)is available for various wavelengths and with aperture sizes between 10 mm and 30 mm, covering the wide range of applications requiring high repeatability. This is particularly important in high-precision areas such as the electronics industry, but can also be used for special marking requirements.

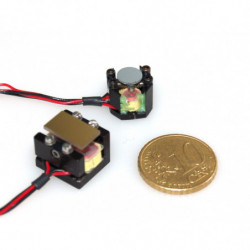

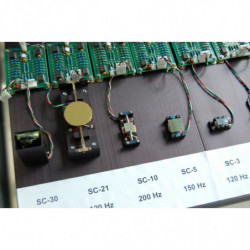

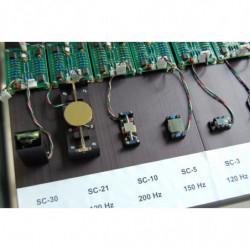

For lower requirements, the less expensive UniScan model should be used.

| ExtraScan | Features (values apply for 10 mm aperture) |

|---|

| Wavelengths | 355 nm, 532 nm, 1064 nm, 10.6 µm |

| Input Beam Aperture | 10 mm, 14 mm, 20 mm, 30 mm |

| Beam Displacement (max.) | 12.54 mm |

| Tracking Error | 0.3 ms |

| Repeatability | <1 µrad |

| Offset Drift | <15 µrad/K |

| Gain Drift | <8 ppm/K |

| Long-term drift over 8h | <0.3 mrad |

| 1 % Full Scale | 0.55 ms |

| 10 % Full Scale | 1.4 |

| Positioning Speed | 7 m/s |

| Typical Scan Angle | ± 12.5° |

| Gain Error | <5 mrad |

| Zero Offset | <5 mrad |

| Nonlinearity | <0.1 % |

| Power Requirements | ±15VDC, ?3A |

| Digital-Interface | XY2-100 |

| Operating Temperature | 25 ±10 °C |

| Weight | 1.9 kg |

Applications

- Ablation

- Welding

- Marking

- Coding