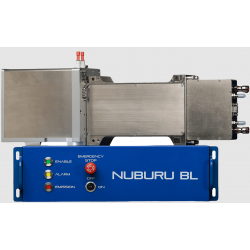

Blue laser source with the highest beam quality for material processing

Reference number: NUB-BL-Series

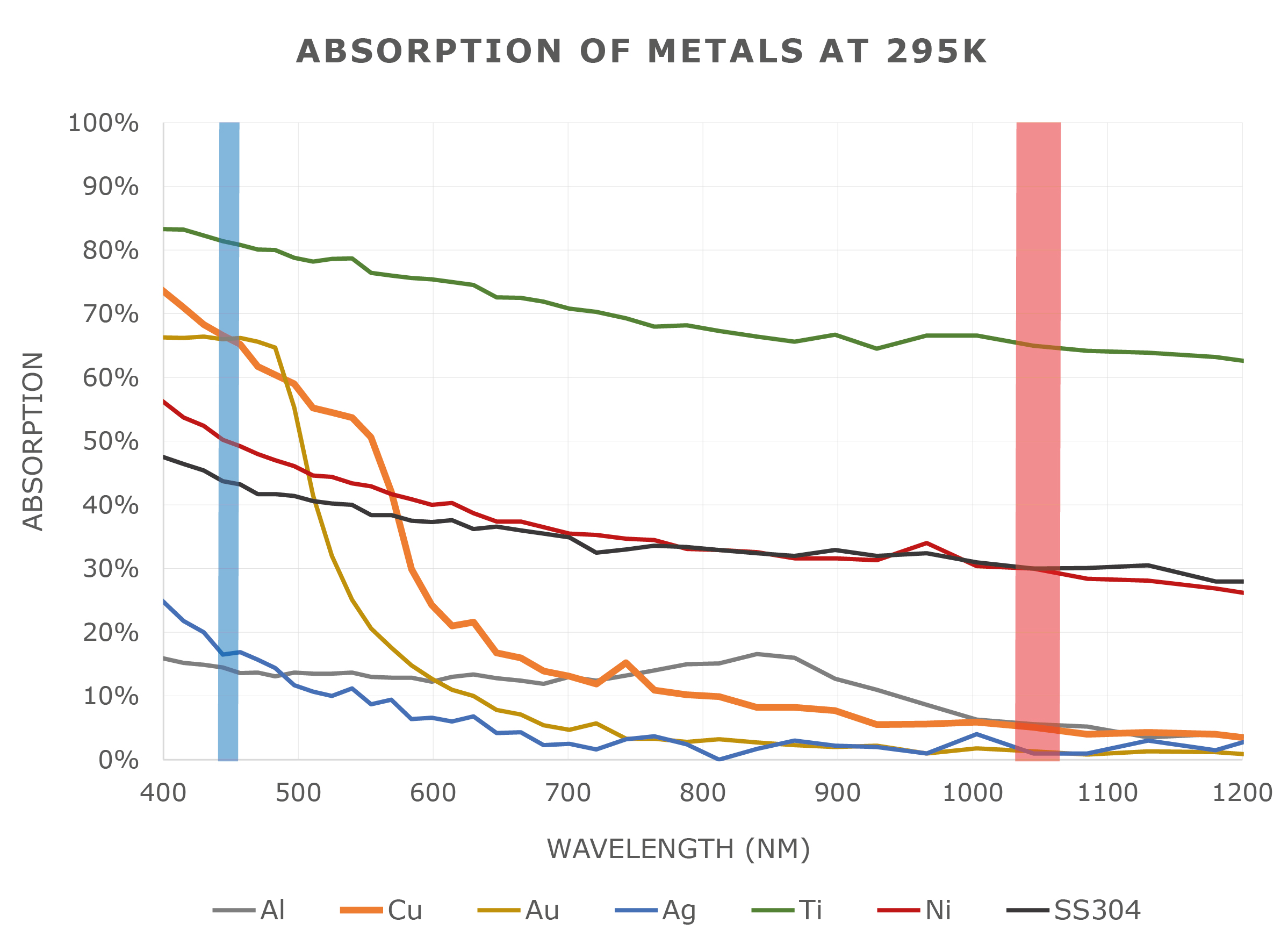

A revolution in material processing: setting new benchmarks in high power blue laser technology. This innovation in precision engineering has led to the creation of BL-Series variants that are optimized to deliver exception performance, versatility and unmatched beam quality for blue laser sources. The application range is wide, but especially for non-ferrous metals are in focus (copper laser welding, gold laser welding).